Wood carving, an ancient craft with a rich history spanning various cultures, has undergone a dramatic transformation with the advent of modern technology. From traditional hand-carving techniques passed down through generations to the integration of sophisticated machinery and software, modern wood carving today merges artistic expression with technological innovation.

**Historical Context**

Traditionally, wood carving has relied heavily on the skill and dexterity of the artisan. Tools such as chisels, knives, and gouges were meticulously used to create intricate designs ranging from simple household items to elaborate religious icons and decorative art. The process was labor-intensive and time-consuming but yielded products of immense cultural and aesthetic value.

**Technological Advancements in Wood Carving**

The industrial revolution marked the beginning of significant changes in wood carving technology. The introduction of power tools revolutionized the carving process, allowing for greater precision and faster production times. However, it is the more recent digital revolution that has truly transformed modern wood carving.

1. **Computer Numerical Control (CNC) Machines**

CNC machines have become a game-changer in the wood carving industry. These machines are programmable and can produce complex designs with remarkable precision and consistency. By converting digital designs into physical objects, CNC technology has opened up new possibilities for large-scale production and intricate detailing that would be highly challenging to achieve manually.

2. **Laser Cutting and Engraving**

Laser technology has also made significant inroads into wood carving. Laser cutters and engravers use high-powered beams to cut or etch designs into wood with unmatched intricacy. This method is not only faster than traditional carving but also allows for a level of detail that is difficult to achieve using hand tools. Additionally, laser technology can work with various types of wood, expanding the range of possible applications.

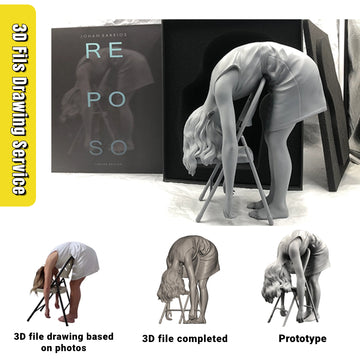

3. **3D Printing**

Though not traditionally associated with carving, 3D printing is beginning to influence the field of wood art. By using wood filaments, a blend of wood fibers and thermoplastic, 3D printers can create objects with the look and feel of real wood. While still in its nascent stage, this technology holds promise for custom, on-demand production of wood-like objects.

4. **Design Software**

Design software has revolutionized the conceptual phase of wood carving. Programs such as AutoCAD, Rhino, and Fusion 360 allow artists to create detailed 3D models of their designs before any physical carving begins. This capability not only aids in planning and visualization but also ensures that the final product aligns closely with the artist’s vision.

**Applications of Modern Wood Carving Technology**

The integration of modern technology into wood carving has expanded its applications beyond traditional boundaries.

1. **Furniture Design**

Modern wood carving technology is extensively used in the furniture industry. CNC machines and laser cutters enable the mass production of intricately designed furniture pieces that stand out in a crowded market. Moreover, digital design tools allow for the customization of pieces tailored to individual client specifications.

2. **Architectural Elements**

Architectural woodwork, such as decorative panels, moldings, and staircases, has greatly benefited from advancements in carving technology. CNC and laser systems can produce complex designs that add a unique aesthetic to buildings, both residential and commercial.

3. **Art and Sculpture**

Contemporary artists increasingly incorporate technology into their practice to create wood sculptures and installations that are both innovative and technically challenging. CNC and laser technology, combined with traditional hand-finishing techniques, allow for the creation of stunningly detailed and imaginative works of art.

4. **Restoration and Conservation**

Modern carving technology also plays a crucial role in the restoration of historical wooden artifacts and buildings. CNC machines can replicate missing or damaged parts of historical pieces with high accuracy, ensuring that restorations remain true to the original designs.

**Challenges and Considerations**

Despite the numerous advantages, the integration of modern technology into wood carving does come with its challenges. The initial investment in high-tech equipment can be substantial, and there is a learning curve associated with mastering new tools and software. Additionally, there are concerns about the loss of traditional hand-carving skills and the cultural heritage they represent.

**The Future of Wood Carving**

Looking ahead, the continued evolution of technology promises even greater advancements in wood carving. Developments in artificial intelligence and machine learning could lead to more intuitive carving machines capable of understanding and executing artistic nuances. Augmented reality (AR) and virtual reality (VR) could provide artists with new ways to visualize and plan their work in a 3D virtual space before commencing physical carving.

In conclusion, the development and application of modern wood carving crafts technology represent a harmonious blend of tradition and innovation. While preserving the artisanal essence of wood carving, technology enhances precision, efficiency, and creative possibilities, shaping the future of this timeless craft in exciting new ways.

Please feel free to try contact us HiMe Rapid Solution Phone/Whatsapp +8615361573721 josen@himetrade.com if you are interested.