In recent years, Binder Jetting technology has emerged as a game-changer in Sand 3D Printing and Sand Mold Additive Manufacturing. This innovative process is transforming the way large, complex structures are manufactured by combining speed, efficiency, and cost-effectiveness, making it ideal for industries such as automotive, aerospace, and art sculpture production.

Life size Michael Jackson sands sculpture

What is Binder Jetting?

Binder Jetting is an additive manufacturing process where a binding agent is selectively deposited onto layers of sand to create solid shapes. Unlike other 3D printing methods that rely on laser or thermal fusion, Binder Jetting’s unique approach makes it exceptionally suited for creating large-scale molds and parts. The technology allows manufacturers to form detailed sand molds with smooth surfaces and customized textures, often needed in casting and molding applications.

3DP Machine

3DP Machine

Why Choose Sand 3D Printing?

Using sand as a primary material has several advantages. Sand 3D Printing is sustainable, as the sand can often be recycled, and it’s accessible due to its affordability. Combined with Binder Jetting, Sand 3D Printing can achieve quick production times without sacrificing precision. It’s a go-to solution for industries that need functional prototypes, molds for metal casting, or high-durability parts.

Fine surface

Fine surface

Applications in Sand Mold Additive Manufacturing

Sand Mold Additive Manufacturing allows companies to create custom, large-scale designs without the need for traditional mold-making tools. This is especially useful in applications such as:

- Automotive: Rapid prototyping of engine components or custom parts.

- Aerospace: Complex, lightweight molds for high-strength components.

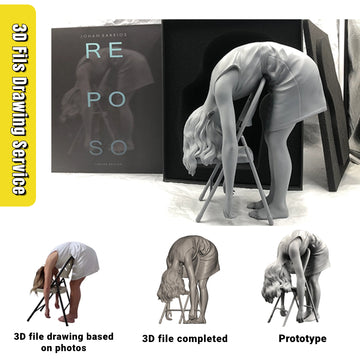

- Art & Architecture: Large, customized structures and sculptures with intricate details.

By eliminating the need for hard tooling and molds, Sand Mold Additive Manufacturing saves time and reduces costs, making it a highly competitive option.

Bronze paint

Bronze paint

Advantages of Binder Jetting in Sand Mold Additive Manufacturing

- Speed: Binder Jetting is faster than traditional methods, making it ideal for urgent production schedules.

- Customization: It allows for precise control over part geometry and texture, creating parts that are tailor-made for specific uses.

- Cost-Efficiency: Compared to traditional manufacturing, Binder Jetting for Sand Mold Additive Manufacturing can be significantly more affordable, especially when creating low to medium-volume production runs.

Final Thoughts

As Binder Jetting continues to evolve, its role in Sand 3D Printing and Sand Mold Additive Manufacturing will expand, offering innovative solutions that bridge the gap between customization and efficiency. Whether you're a designer, engineer, or manufacturer, exploring Binder Jetting for your next project could unlock a world of creative and functional possibilities. A lamp of great artistic value

A lamp of great artistic value

Welcome to contact us to learn more

Josen@himetrade.com

86 15361573721